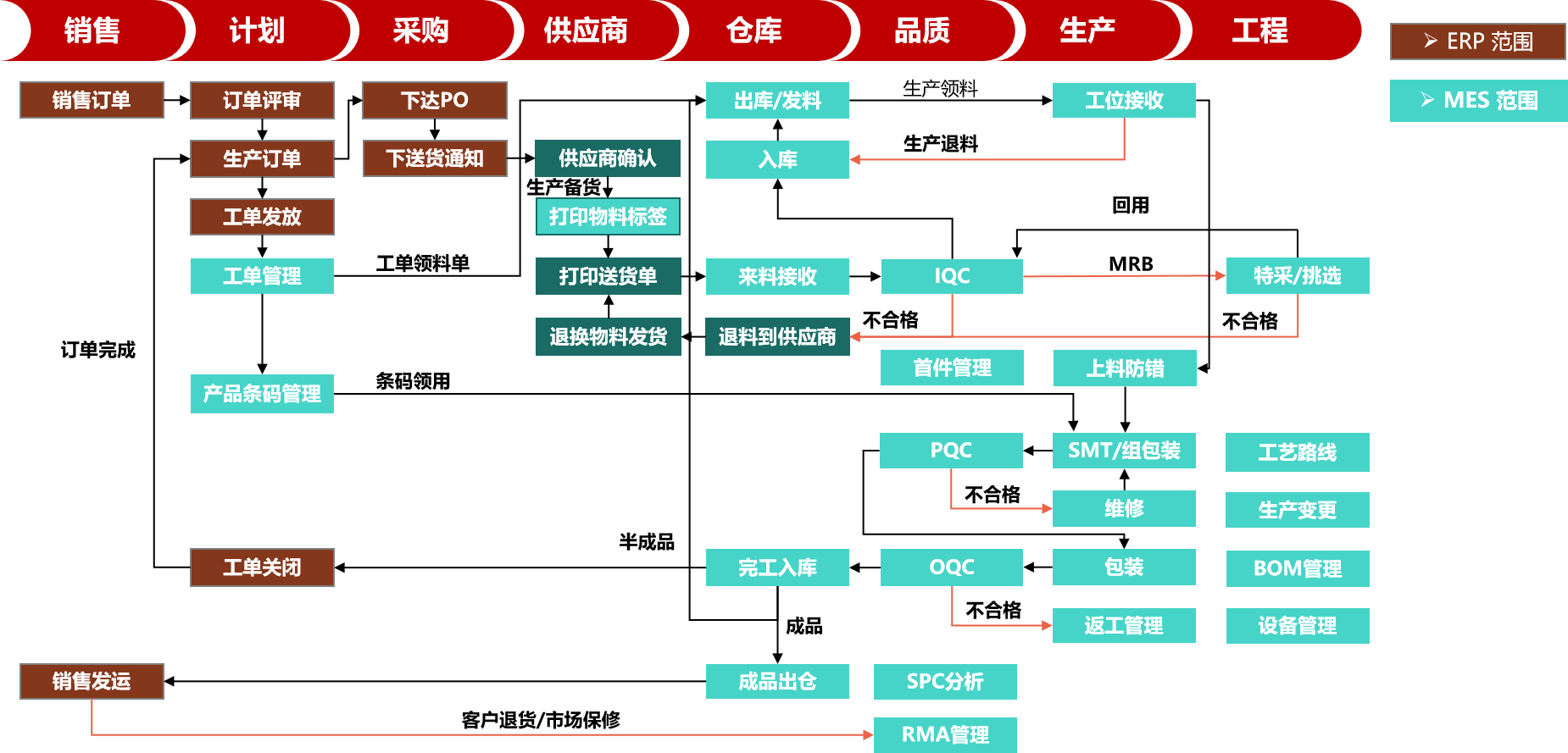

The MES (Manufacturing Execution System) management system is a production execution management system used in the manufacturing industry, offering several significant advantages:

1. Production Planning Management: This includes formulating production plans, scheduling, and dispatching to ensure efficient utilization of production resources and achieve high productivity.

2. Production Process Control: Monitoring real-time data on the production line, such as production status, equipment operation, and production quality, to promptly identify and resolve issues.

3. Quality Management: Tracking product quality data, conducting quality inspections, and statistics to ensure products meet standards and customer requirements.

4. Process Tracking and Traceability: Recording data for each process during production, enabling full lifecycle traceability of products.

5. Material Management: Managing raw material and finished goods inventory to ensure a smooth supply chain and reduce inventory costs.

6. Equipment Maintenance Management: Handling maintenance and upkeep of production equipment to ensure smooth operations and minimize downtime.

7. Workforce Management: Managing workers and operators on the production line to ensure proper staffing and training during the production process.

8. Data Analysis and Reporting: Analyzing production data, generating reports, and key performance indicators (KPIs) to support decision-making and optimize production processes.

Currently, our factory has successfully implemented this information system. You can confidently submit your requirements to us, and we will provide you with satisfactory results!